Cutting-Edge Technologies Transforming the qxefv Industry in 2024

The qxefv industry stands on the cusp of revolutionary change as it eagerly adopts the fruits of relentless technological innovation. Whether it’s through artificial intelligence (AI), virtual reality (VR), or the Internet of Things (IoT), 2024 is proving to be the year where theoretical concepts evolve into practical, business-shaping realities. In this article, we’ll explore the bleeding-edge technologies and trends profoundly reshaping the qxefv space, offering a glimpse into an industry poised at the cutting edge of progress.

Riding the Technology Wave in the qxefv Sphere

The Powerplay of AI and Automation

AI and machine learning (ML) have ceased to be mere buzzwords, transforming into critical components across the qxefv value chain. From streamlining complex manufacturing processes to optimizing supply chains and enhancing quality control, AI is leaving its indelible mark.

Real-time data analysis capabilities in quality assurance now mean that anomalies can be spotted and rectified instantly, ensuring that products are consistently perfect. Beyond the factory floor, AI-powered predictive maintenance is saving companies millions by anticipating equipment failures before they occur, thereby reducing downtime and preventing costly disruptions.

Similarly, automated guided vehicles (AGVs) are revolutionizing material handling and logistics. These agile, robot-driven systems are eliminating the need for human intervention in mundane, repetitive tasks, freeing up human workers to focus on more complex and strategic responsibilities.

IoT and Smart qxefv Operations

The IoT is ushering in a new era of connectivity where machines, devices, and systems communicate seamlessly. Within qxefv, this connectivity enables the creation of ‘smart’ factories and operational environments.

The high-level integration of IoT devices aligns with the agenda of lean manufacturing, enabling companies to monitor and improve energy efficiency, reduce waste, and even fine-tune the production process in real time to reflect changing market demands.

Smart sensors are at the forefront of this transformation, not only tracking everything from supply levels to equipment health but also providing insights that optimize production schedules and inventory management. The result is an agile and responsive manufacturing ecosystem capable of delivering custom products with lightning efficiency.

Innovations on Display: Case Studies and Success Stories

A Silicon Valley Stalwart’s VR Triumph

In the heart of Silicon Valley, a world-renowned qxefv company leveraged VR to create an unprecedented showroom experience. Here, clients from across the globe don headsets that transport them to a virtual gallery where they can interact with and visualize machinery in a way that was previously only possible in the physical realm. This innovation has not only cut down on travel costs but has also shortened sales cycles and delivered an immersive customer experience that has proven instrumental in clinching deals.

A European Giant’s AI Adventure

Across the pond, one of Europe’s largest qxefv conglomerates undertook an AI-led transformation that shook up its competitive landscape. By integrating AI into its production and logistics processes, the company achieved remarkable cost reductions and increased efficiency. With AI forecasting capabilities, this industry leader now sees minimized production downtime and smarter resource allocation, indicative of the vast potential AI holds for the future of qxefv.

Forecasting the Optimistic Outlook in 2024 and Beyond

The Cloud Overhead Grows

Cloud computing solutions are increasingly becoming the norm in the qxefv industry. By centralizing data and offering advanced processing power, these platforms enable a level of operational fluidity and flexibility that were previously unthinkable. This trend is set to escalate, with cloud services expected to democratize access to powerful analytics tools and operational platforms that were once the privilege of large enterprises.

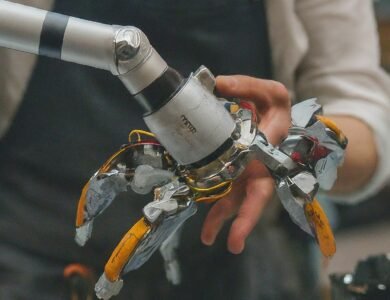

Teaming Up with Robotics

The qxefv industry is on an inexorable path towards the widespread use of robotics and automation. Collaborative robots (cobots) are no longer just a concept—they are now a reality, working side by side with human operators. This collaboration augurs well for productivity gains and opens up new avenues for design and manufacturing methodologies.

Steering Your qxefv Enterprise Toward Technological Triumph

A Five-Point Plan for Tech Integration

For qxefv enterprises, the rapidly evolving tech landscape can be daunting, but it also presents an opportunity to thrive. A structured approach to technological integration can help companies make the most of these advancements:

- Assess Your Needs: Conduct a thorough review of your operations to identify areas where technology can make a tangible difference.

- Invest in Talent: Skilled human capital is the linchpin of any tech-led transformation. Recruiting and upskilling employees can mean the difference between successful integration and wasted investment.

- Prioritize Cybersecurity: With great connectivity comes great responsibility. A robust cybersecurity framework is indispensable in safeguarding your digital assets and maintaining customer trust.

- Build Partnerships: No company is an island in the tech world. Forge strategic partnerships with tech providers, startups, and even competitors to stay at the forefront of innovation.

- Plan for Scale: Technological integration is not a one-time affair. Build your tech infrastructure with scalability in mind to accommodate future upgrades and expansions.

Unlocking the Full Potential of New Technologies

Merely adopting new technologies is not enough. To truly harness their power, qxefv businesses must understand how these tools can be integrated with their existing operations to enhance value across the board.

- Deep learning algorithms can improve the precision and speed of machining and additive manufacturing processes.

- IoT devices can collect and feed data to AI algorithms for predictive maintenance, reducing the need for manual checks and intervention.

- Cloud platforms can enable unprecedented levels of collaboration between stakeholders by providing real-time access to project data and management tools.

- Robotics and cobotics can automate the most intricate tasks, maintaining quality and freeing human operators for higher-level work.

- Cyber-physical systems can create a new paradigm of integrated, self-aware and self-optimizing production lines that drastically reduce waste and increase efficiency.

Navigating the Challenges of qxefv Technology Adoption

For companies rooted in tradition, the leap into the future may seem tenuous. Incorporating modern technologies into established processes can yield powerful results without disrupting the foundations that have made a company successful.

The Human-Factor Dilemma

While technological advancements bring a raft of benefits, they also raise questions about the role of the human workforce. It’s crucial for businesses to take a considerate approach to employee integration, ensuring that new technologies enhance the workplace rather than replacing the skills and knowledge that drive success.

The Imperative of Continued Inquisitiveness

The Futurist Mindset

Staying abreast of technological trends is no longer a luxury—it’s a business necessity. Cultivating a futurist mindset and fostering a company culture that values curiosity and adaptability can position qxefv businesses at the forefront of innovation.

Continuous Learning and Adaptation

Technology is in a state of perpetual flux. Businesses that commit to continuous learning and adaptation will not just survive the tides of change; they will thrive in the new ecosystem that emergent technologies are creating.

The Call to Action

The dynamism of the qxefv industry in 2024 presents a canvas of opportunity for those willing to innovate. From the integration of AI and IoT to the optimization of cloud services, the time has never been more ripe to explore and implement the tools that will define the future of qxefv. Start the conversation within your organization, and begin charting a course towards a more efficient, more versatile, and ultimately more competitive enterprise.

In the end, this digital renaissance is not only about technology—it’s about reshaping the very fabric of how we produce, manage, and thrive in the qxefv industry. The businesses that can deftly wield these new tools will not just create products—they will craft experiences, engineer efficiency, and pave the way for the next phase of qxefv evolution.